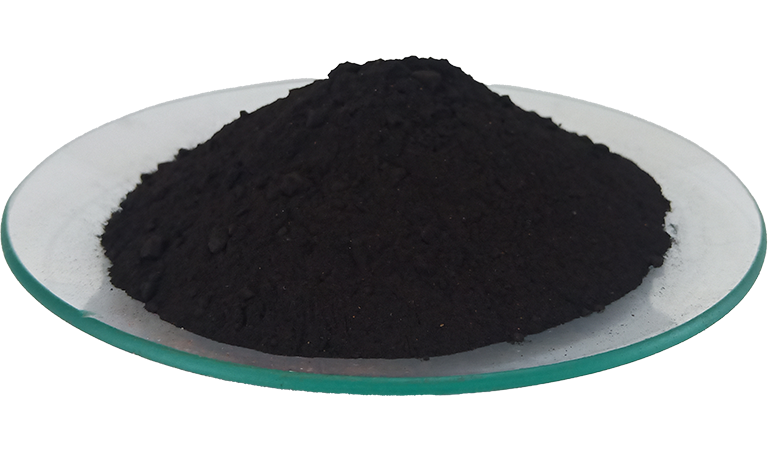

Silver-Coated Copper Powder

Product Introduction

Silver coated copper powder is a composite metal powder made by coating a layer of silver on the surface of copper powder. This material combines the excellent electrical conductivity of copper with the oxidation resistance of silver, thereby enhancing overall performance. Silver coated copper powder is widely used in the electronics industry, becoming the preferred material for many high-performance applications. Its main characteristics include excellent electrical conductivity and oxidation resistance, while being more cost-effective than pure silver powder. This makes silver coated copper powder highly advantageous and technically superior for large-scale production and high-performance applications.

Silver coated copper powder not only has excellent electrical conductivity and oxidation resistance but can also replace pure silver powder in many applications, significantly reducing costs. This makes silver coated copper powder widely used in electronic components, conductive adhesives, conductive paints, and conductive inks. Particularly in electrode materials, AB glue, EMI shielding, and medical instrument conductivity, silver coated copper powder shows its superior performance and versatility. With continuous technological advancements, the application range of silver coated copper powder may further expand, bringing dual benefits of performance improvement and cost reduction to more fields.

The versatility and superior performance of silver coated copper powder play a significant role in the electronics industry, and its application range may further expand with technological advancements.

Specifications and Ingredients

The silver coated copper powder produced by our company has the following features:

- Silver coating rate: High purity silver coating ensures excellent electrical conductivity and stability.

- Oxidation resistance: Excellent oxidation resistance extends product life.

- Conductivity and resistivity: High conductivity and low resistivity make it suitable for high-precision electronic applications.

- Dispersion performance: Good dispersibility ensures uniform distribution in various substrates.

We can provide various specifications of silver coated copper powder products according to customer needs, including different particle sizes and silver content, to meet various application requirements.

Features and Applications

Main Features of Silver Coated Copper Powder

Silver coated copper powder has many excellent properties, making it widely applicable in the electronics industry. Firstly, the silver coating significantly enhances the electrical conductivity of the copper powder, making silver coated copper powder capable of providing stable electrical conductivity in electronic component connections. Secondly, the silver layer effectively prevents oxidation, extending the material's lifespan, which is particularly important for electronic applications requiring long-term stability. Additionally, compared to using pure silver powder, silver coated copper powder can significantly reduce costs, especially in large-scale production, making it a high-cost-performance choice.

Electrical conductivity: The silver layer enhances the conductivity of copper powder, making it perform better in electronic applications.

Oxidation resistance: The silver layer effectively prevents oxidation, extending the material's lifespan.

Cost-effectiveness: Compared to using pure silver powder, silver coated copper powder can significantly reduce costs, especially in large-scale production.

These characteristics of silver coated copper powder make it an ideal material for high performance and cost-effectiveness in the electronics industry.

Applications of Silver Coated Copper Powder in Conductive Adhesives

Silver coated copper powder is widely used in conductive adhesives. Conductive adhesives are crucial materials for connecting electronic components, providing stable electrical conductivity. Silver coated copper powder ensures the stability and reliability of conductive adhesives during long-term use through its excellent conductivity and oxidation resistance. This material not only improves the performance of conductive adhesives but also significantly reduces costs, making it an important material in the electronics industry.

During the manufacturing process of conductive adhesives, silver coated copper powder can be uniformly distributed in

the adhesive, forming a good conductive network. This enables the conductive adhesive to form a stable current path between electronic components, enhancing the overall performance of the product. Conductive adhesives are widely used in electrode materials, AB glue, and other high conductivity fields, demonstrating the versatility and superior performance of silver coated copper powder.

- Enhancing the conductivity of conductive adhesives

- Improving the oxidation resistance and lifespan of conductive adhesives

- Significantly reducing production costs

The application of silver coated copper powder in conductive adhesives not only improves product performance but also effectively reduces costs, making it an ideal material in the electronics industry.

Applications of Silver Coated Copper Powder in Conductive Paint

Silver coated copper powder is crucial in conductive paint applications. Conductive paint is a special coating applied to the surface of electronic devices to enhance their conductivity and anti-interference performance. Silver coated copper powder can significantly enhance the performance of conductive paint with its excellent conductivity and oxidation resistance.

During the manufacturing process of conductive paint, silver coated copper powder can be evenly dispersed in the paint, forming a continuous conductive layer. This conductive layer can effectively shield electromagnetic interference (EMI), protecting electronic devices from external electromagnetic waves. At the same time, the presence of the silver layer can extend the lifespan of the conductive paint, ensuring its long-term stable conductive performance.

- Enhancing the conductivity of conductive paint

- Improving the oxidation resistance and lifespan of conductive paint

- Effectively shielding electromagnetic interference (EMI)

The application of silver coated copper powder in conductive paint not only enhances the performance of the coating but also effectively protects electronic devices, ensuring their excellent performance in harsh environments.

Applications of Silver Coated Copper Powder in Conductive Ink

Silver coated copper powder is widely used in conductive ink, especially in printed circuit boards (PCBs) and other electronic products. Conductive ink is a material that can print conductive patterns on various substrates, and the addition of silver coated copper powder can significantly enhance the conductivity and stability of conductive ink.

Silver coated copper powder can be evenly distributed in the ink, forming a continuous conductive network, which is crucial for applications such as printed circuit boards. This conductive network not only ensures stable current transmission but also provides good oxidation protection, ensuring that the circuit remains stable during long-term use.

- Enhancing the conductivity of conductive ink

- Improving the oxidation resistance and lifespan of conductive ink

- Ensuring the stability of printed circuit boards

The application of silver coated copper powder in conductive ink ensures the stability and reliability of electronic products during long-term use, significantly enhancing the overall performance of the product.

Frequently Asked Questions

Question 1: What are the applications of silver coated copper powder in electronic components?

Silver coated copper powder is widely used in electronic components for manufacturing electrode materials, conductive adhesives, conductive inks, and conductive paints, ensuring stable electrical conductivity and long-term lifespan.

Question 2: How is the electrical conductivity of silver coated copper powder improved?

The electrical conductivity of silver coated copper powder is mainly improved by coating a layer of silver on the surface of copper powder. The silver layer significantly enhances the conductivity of the copper powder, making it perform better in electronic applications.

Question 3: What are the use scenarios of silver coated copper powder in protective coatings?

Silver coated copper powder is mainly used in protective coatings to provide conductivity and oxidation protection, applied to the surface coating of electronic devices to enhance their protective performance.

Question 4: How does the thermal conductivity of silver coated copper powder affect the operation of electronic devices?

The thermal conductivity of silver coated copper powder helps dissipate heat in electronic devices, ensuring that the equipment does not overheat during high-performance operation, thereby improving the stability and lifespan of the equipment.

Question 5: What are the applications of silver coated copper powder in 3D printing?

Silver coated copper powder is used in 3D printing to manufacture conductive components such as antennas and sensors, ensuring that the printed components have good conductivity and structural strength.

Quick Browse All Products

Professional Services

Resource Reuse

Recycling and reuse of waste liquid from printed circuit boards and metal surface treatment, achieving resource circulation and environmental protection.

Learn moreMetal Etchant

Ferric Chloride Solution

Ferric Chloride: An efficient agent for metal etching, water treatment, and various industrial applications.

Learn moreWater Treatment Agents

Ferric Chloride Solution

Ferric Chloride: An efficient agent for metal etching, water treatment, and various industrial applications.

Learn moreFerrous Chloride Solution

Ferrous Chloride: A high-efficiency reducing agent for wastewater treatment, fabric dyeing, and various industrial uses.

Learn morePoly Aluminum Chloride (PAC)

Poly Aluminum Chloride: An efficient wastewater treatment agent, suitable for various types of wastewater, improving treatment efficiency.

Learn moreCalcium Chloride

Calcium Chloride: Used for fluorine-containing wastewater treatment, refrigeration, ice making, and as an antifreeze in construction.

Learn moreDiverse Copper Metals

Copper Powder

Copper Powder: High purity, suitable for powder metallurgy, electronic components, and chemical catalysts.

Learn moreCopper Oxide Powder

Copper Oxide: Used in catalysts, glass coloring, analytical reagents, and petroleum desulfurization.

Learn moreCuprous Oxide Powder

Cuprous Oxide: Used in antifouling paint, pesticides, red glass, and copper salt production.

Learn moreSilver-Coated Copper Powder

Silver-Coated Copper Powder: Enhances conductivity and oxidation resistance, suitable for conductive adhesives, paints, and inks.

Learn more