Progress in the Application of Nanoscale Copper Powder in 3D Printing

This article was last updated on August 12, 2024

Characteristics of Nanoscale Copper Powder and Its Advantages in 3D Printing

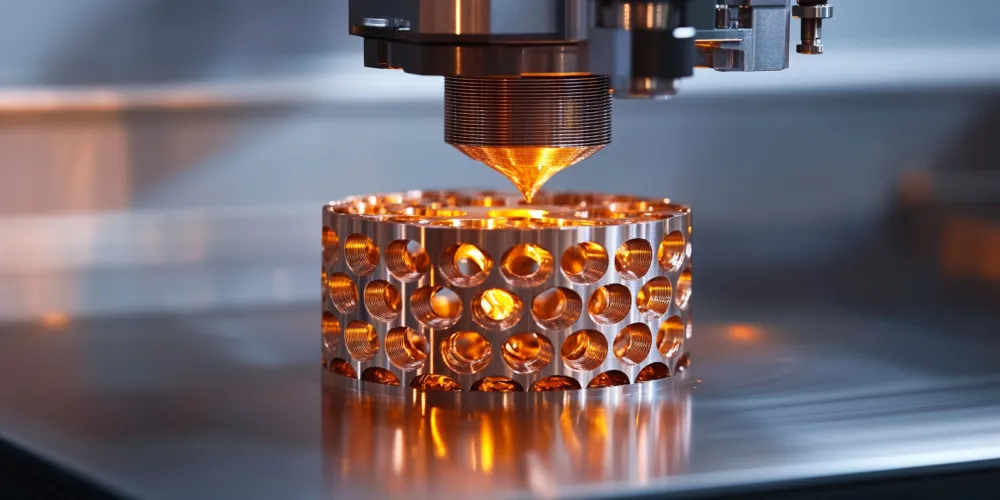

Nanoscale Copper Powder, as an emerging 3D printing material, is revolutionizing the field. This material typically has a particle size of less than 100 nanometers, offering unique physical and chemical properties that show great potential in 3D printing.

The main characteristics of nanoscale copper powder include:

- Extremely high specific surface area

- Excellent electrical and thermal conductivity

- Good flowability and sintering properties

- Tunable surface characteristics

These characteristics make nanoscale copper powder excel in the 3D printing process, allowing the production of high-precision and high-performance metal parts. Its application in 3D printing is gaining increasing attention.

In 3D printing, nanoscale copper powder exhibits several advantages:

- Higher printing precision: Due to its extremely small particle size, nanoscale copper powder can achieve finer detail printing, especially suitable for manufacturing microelectronic components (Submicron Particles for Microelectronic Components).

- Better conductivity: Parts made from nanoscale copper powder have lower resistivity, which is especially important in electronics manufacturing, making it ideal for use in conductive paste and MLCC (Multilayer Ceramic Capacitors).

- Faster printing speed: The good flowability and sintering properties of nanoscale copper powder allow for faster printing speeds, improving production efficiency.

- Stronger mechanical properties: By optimizing particle size distribution and surface treatment, the strength and toughness of printed parts can be significantly enhanced, suitable for manufacturing porous materials and metal matrix composites.

These nanoscale copper powder products have been applied in various industries, including electronics manufacturing and aerospace parts. Nanoscale copper powder used for 3D printing micro heat sinks not only improves heat dissipation efficiency but also reduces material waste.

Application of Nanoscale Copper Powder in the Electronics Manufacturing Industry

In the electronics manufacturing industry, nanoscale copper powder is opening up new applications for 3D printing technology. The unique properties of this material offer significant advantages in manufacturing complex electronic components and circuits.

The main applications of nanoscale copper powder in the electronics manufacturing industry include:

- Manufacturing micro antennas for 5G communication devices and IoT devices

- High-efficiency heat sinks for high-performance computing devices and electric vehicle power systems

- Flexible circuits for wearable devices, conductive layers for foldable screens

- Micro connectors for miniaturized electronic devices and high-density circuit boards

An ultra-fine nanoscale copper powder used for 3D printing 5G antennas not only enables complex antenna structures but also greatly enhances signal reception capabilities.

In the field of heat dissipation, a highly efficient 3D printed heat sink adopts a bionic design, with an internal structure that mimics tree branches, significantly increasing the heat dissipation area.

In terms of flexible circuits, nanoscale copper powder also shows unique advantages. A special nanoscale copper ink developed can be directly printed on flexible substrates to form conductive paths. This technology successfully produced a lightweight and comfortable smart wristband.

Nanoscale copper powder is changing the game in the electronics manufacturing industry. It not only enables more complex designs but also improves product performance and reduces material waste. As technology continues to advance, nanoscale copper powder will find applications in more electronic products.

Application of Nanoscale Copper Powder in Aerospace and Defense Industries

In the aerospace and defense industries, nanoscale copper powder is gradually becoming a key material for 3D printing technology. The unique properties of this material provide significant advantages in manufacturing high-performance, lightweight aerospace parts and defense equipment.

The main applications of nanoscale copper powder in the aerospace and defense industries include:

- Lightweight structural components: Internal support structures for aircraft wings, satellite antenna brackets

- Efficient cooling systems: Cooling systems for aircraft engines, high-power radar equipment heat sinks

- Electromagnetic shielding components: Military communication equipment housings, satellite electronic system shields

- Precision mechanical parts: Nozzles for rocket propulsion systems, lightweight gearboxes for drones

Nanoscale copper powder has been used to 3D print satellite antenna brackets, which not only have extremely high strength and lightweight characteristics but also maintain stability in space environments.

In terms of electromagnetic shielding, nanoscale copper powder also shows unique advantages. This special nanoscale copper composite material can be directly 3D printed into various shapes of electromagnetic shielding enclosures. This technology has successfully produced a lightweight and highly effective communication equipment housing.

In precision mechanical parts manufacturing, the application of nanoscale copper powder has also brought revolutionary changes. The internal cooling channels of a high-performance rocket nozzle adopt a complex spiral structure, greatly improving cooling efficiency and jet performance.

Nanoscale copper powder is opening up new possibilities for the aerospace and defense industries. It not only enables more complex designs but also significantly improves part performance while reducing weight.

Future Development Trends of Nanoscale Copper Powder in 3D Printing

With the continuous advancement of 3D printing technology and the in-depth development of nanomaterials science, the application prospects of nanoscale copper powder in the 3D printing field are becoming increasingly broad. The development of technology has led to widespread application of this material in various fields.

Here are a few development trends worth noting:

- Multifunctional composites: Development of composite powders combining nanoscale copper with other materials, research on smart materials with special functions

- Precision control technology: Improving the uniformity of nanoparticle sizes, developing new surface treatment technologies

- Green manufacturing: Development of environmentally friendly nanoscale copper powder production processes, exploration of recycling technologies for nanoscale copper powder

- High-performance applications: Development of nanoscale copper powder for superconducting materials, research on the application of nanoscale copper powder in quantum computing hardware

In the field of multifunctional composites, the combination of nanoscale copper with graphene is becoming a new research hotspot. This composite material not only has excellent electrical and thermal conductivity but also has extremely high mechanical strength, with broad application prospects in the aerospace and defense fields.

In terms of precision control technology, a new vapor-phase preparation technology has been successfully developed, capable of producing nanoscale copper powder with extremely narrow particle size distribution. This highly uniform nanoscale powder significantly improves the performance consistency of 3D printed parts.

The future development of nanoscale copper powder is not only limited to improving material performance but also focuses on developing smart materials with entirely new functions, which will bring unprecedented application possibilities.

In the field of green manufacturing, significant progress has been made in wet chemical preparation technology, which not only significantly reduces energy consumption but also reduces harmful gas emissions. At the same time, how to recycle copper resources from discarded electronic products and turn them into high-quality nanoscale copper powder has become an important research direction.

High-performance applications are another important development direction. The application range of nanoscale copper powder will include the manufacture of superconducting materials and research on quantum computing hardware. By precisely controlling the size and surface properties of nanoscale copper powder, it is expected to significantly improve the critical performance of these materials.

The application of nanoscale copper powder in the field of 3D printing is just beginning. As technology continues to advance, this material will play an increasingly important role in more fields, driving the manufacturing industry toward higher-end and more precise directions.

Looking to the future, the application of nanoscale copper powder in the field of 3D printing will continue to expand and deepen. From electronics manufacturing to aerospace and defense, from new energy technologies to green manufacturing, this material will play an increasingly important role. With the growing global demand for high-performance and multifunctional materials, the market prospects for nanoscale copper powder are very promising.

Overall, the application of nanoscale copper powder in the field of 3D printing is in a rapid development stage, with the future full of opportunities and challenges. As technology continues to advance and the application fields continue to expand, this material will bring more possibilities for manufacturing innovation and product innovation.

Related Articles

Progress in the Application of New Nanoscale Copper Oxide Powder

This article discusses the breakthrough application of new nanoscale copper oxide powder in electronics manufacturing, showcasing its potential in improving product performance, reducing costs, and driving industrial upgrades.

Learn MoreSharing Eco-friendly Copper Oxide Technology

This article introduces the eco-friendly copper oxide production process, showcasing its technological innovations in reducing energy consumption and emissions, and analyzing its economic benefits and market prospects.

Learn MoreApplication of High Conductivity Silver-plated Copper Powder in 5G Communication Equipment

This article introduces the application of high conductivity silver-plated copper powder in 5G communication equipment, showcasing its excellent performance in conductivity, oxidation resistance, and environmental protection, and discussing its significant effects in improving 5G equipment performance.

Learn MoreSharing New Generation Copper Powder Surface Treatment Technology: Key to Improving Product Stability

This article details the company's latest development in copper powder surface treatment technology, showcasing the breakthrough achievements in improving product stability and exploring future application prospects.

Learn MoreSignificant Progress in the Application of Copper Oxide Powder in Photocatalysis

This article delves into the breakthrough research on the application of copper oxide powder in photocatalysis, showcasing its great potential in environmental technology.

Learn MoreProgress in the Application of Nanoscale Copper Powder in 3D Printing

This article details the latest applications of nanoscale copper powder in 3D printing, showcasing its potential and development trends in various industries.

Learn MoreProspects for the Application of Copper Powder in New Energy Vehicles

This article details the application of copper powder in new energy vehicles, showcasing its key role and future development potential in battery systems, motor systems, and charging equipment.

Learn MoreBreakthrough in Metallurgical Copper Powder Quality Control Technology

This article discusses the new technology for quality control in metallurgical copper powder, showcasing its breakthroughs in improving product quality stability and its application prospects in precision manufacturing.

Learn MoreAdvances in Recycling Technology Promote the Development of the Copper Powder Circular Economy

This article discusses the latest advances in copper powder recycling technology, showcasing its key role in promoting the development of the circular economy and analyzing future trends and market prospects.

Learn More