Prospects of Copper Powder Applications in New Energy Vehicles

Last updated on August 12, 2024

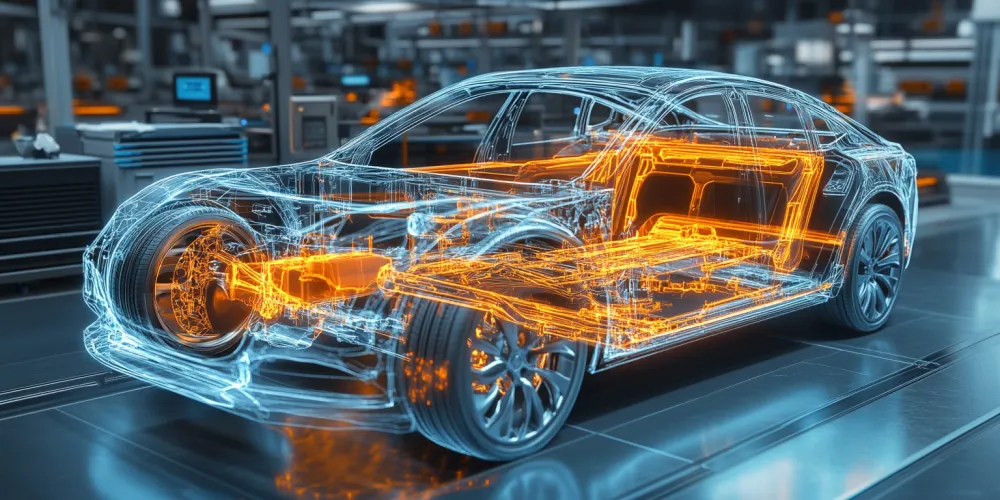

Characteristics of Copper Powder and Its Importance in New Energy Vehicles

Copper powder is a material with unique properties that plays a crucial role in the field of new energy vehicles. This material boasts excellent electrical conductivity, good thermal conductivity, and outstanding corrosion resistance, making it an indispensable raw material for the core components of electric vehicles. As the rapid development of electric vehicles continues, the application scope of copper powder is also expanding.

The main characteristics of copper powder are reflected in the following aspects:

- High Purity: The purity of copper powder can usually reach over 99.9%, ensuring its stability and reliability in applications.

- Controllable Particle Size: Advanced manufacturing processes allow precise control of the particle size distribution of copper powder to meet the needs of different applications.

- Various Shapes: It can be made into various shapes such as spherical and dendritic to suit different forming processes.

- Excellent Sinterability: This facilitates the production of high-density, high-strength parts.

As the Taiwanese government vigorously promotes the green energy industry, the market for new energy vehicles is rapidly expanding, leading to an increasing demand for high-quality copper powder. Taiwan's new energy vehicle industry chain is gradually improving, forming a complete ecosystem from upstream raw materials to downstream vehicle manufacturing. In this system, copper powder, as a key raw material, is of paramount importance.

Applications of Copper Powder in Electric Vehicle Battery Systems

In the heart of electric vehicles—the battery system, copper powder plays a critical role. With the continuous advancement of battery technology, the importance of high-quality copper powder becomes more prominent. Its applications in battery systems are mainly reflected in the following aspects:

- Electrode Materials: Copper powder can be used as an additive in lithium-ion battery anode materials to improve the conductivity of the battery. In solid-state battery technology, copper powder can be used to make current collectors to ensure efficient conduction of internal currents in the battery.

- Conductive Additive: Adding copper powder to cathode materials can significantly enhance the overall conductivity of the battery, helping to reduce internal resistance and improve charging and discharging efficiency.

- Thermal Management Systems: Utilizing the excellent thermal conductivity of copper powder, high-efficiency radiators can be manufactured to help control battery temperature, extend battery life, and improve safety.

- Battery Connectors: Connectors manufactured using copper powder sintering technology have higher conductivity and mechanical strength, ensuring reliable connections between battery modules and reducing energy loss.

As the development of electric vehicle battery technology intensifies across Taiwan, the applications of copper powder are ubiquitous. For example, the next-generation high-energy-density battery uses specially treated copper powder as a conductive additive, increasing the energy density by 15% and improving charging speed by 20%.

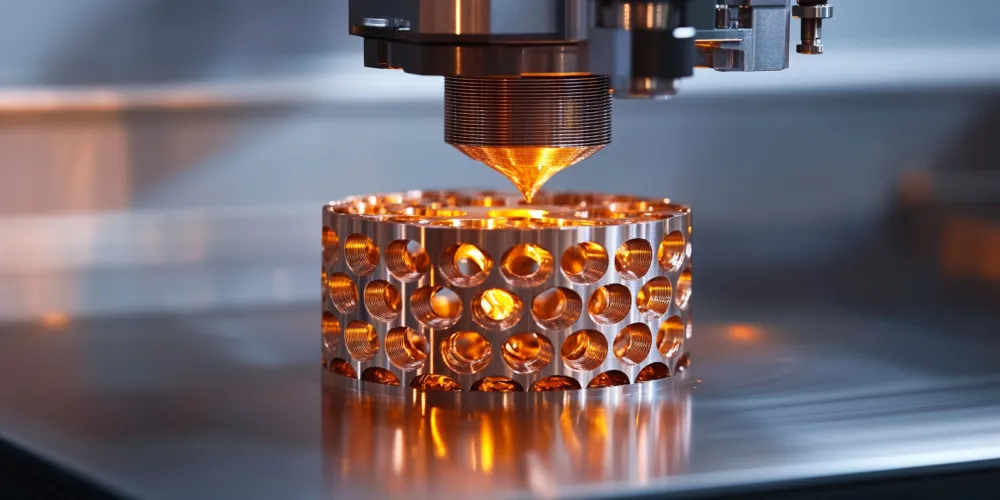

Applications of Copper Powder in Electric Vehicle Motor Systems

The motor system is another core component of electric vehicles, and the application of copper powder in it is equally critical. High-performance motor systems not only enhance vehicle power performance but also significantly improve energy efficiency. The applications of copper powder in electric vehicle motor systems mainly include the following aspects:

- Stator and Rotor: Motors manufactured using copper powder have higher conductivity and magnetic permeability, which can reduce energy loss in motors and improve efficiency.

- Motor Windings: Windings made of high-purity copper powder can increase current density, helping to reduce motor size and increase power density.

- Thermal Management Systems: Utilizing the excellent thermal conductivity of copper powder, high-efficiency motor radiators can be manufactured to ensure temperature stability during high-load operation.

- Brushes and Slip Rings: Brushes and slip rings made using copper powder have lower contact resistance, reducing electrical loss and improving overall motor efficiency.

For example, the newly launched permanent magnet synchronous motor uses copper powder processed with special techniques to make the stator windings, increasing the power density of the motor by 20% while reducing the weight by 15%. This high-performance motor has been adopted by several well-known electric vehicle manufacturers.

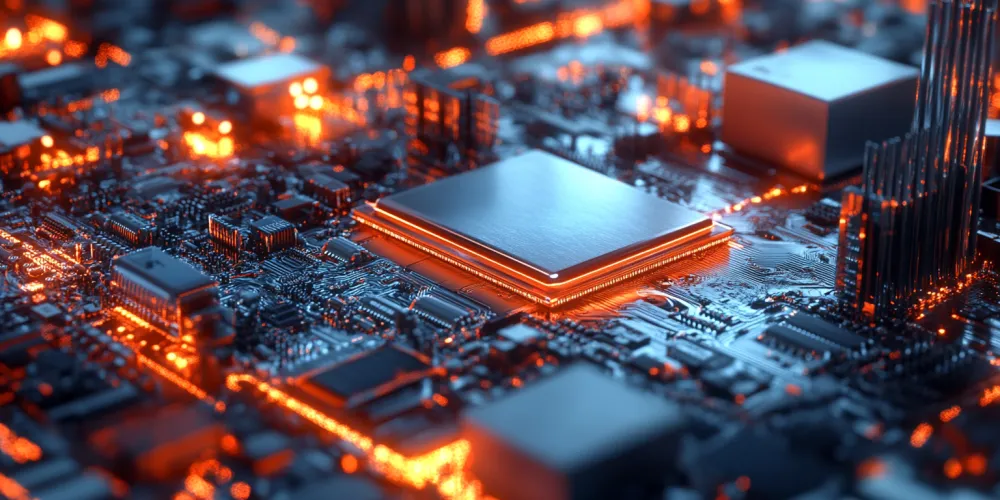

Applications of Copper Powder in Electric Vehicle Electronic Control Systems

Electronic control systems are the brain and nervous system of electric vehicles, responsible for coordinating and managing various subsystems of the vehicle. High-performance electronic control systems not only enhance overall vehicle performance but also optimize energy management and extend the range. The applications of copper powder in electric vehicle electronic control systems are mainly reflected in the following aspects:

- Power Modules: Power module substrates made of copper powder have better thermal conductivity, which can increase power density and reduce module size.

- Printed Circuit Boards (PCBs): High-frequency PCBs made of high-purity copper powder can improve signal transmission quality, helping to reduce electromagnetic interference (EMI) and enhance the reliability of control systems.

- Connectors: High-reliability electronic connectors made with copper powder ensure stable signal and power transmission in harsh environments.

- Thermal Management Systems: Microchannel heat sinks made from copper powder metal matrix composites (MMC) can improve cooling efficiency, effectively solving the heat dissipation problem of highly integrated electronic control units.

For example, a new power module uses copper powder processed with special techniques to manufacture the heat dissipation substrate, increasing heat dissipation efficiency by 25% while reducing the size by 20%. This high-performance power module has already been applied in multiple electric vehicle models.

Applications of Copper Powder in New Energy Vehicle Charging Equipment

With the widespread adoption of electric vehicles, efficient and convenient charging equipment has become an indispensable part of the new energy vehicle industry chain. The application of copper powder in charging equipment provides important support for solving key issues such as fast charging and high-power transmission. Its main application areas include:

- Charging Gun and Connectors: Using high-conductivity copper powder to manufacture charging gun contacts can improve charging efficiency, reduce energy loss during charging, and lower heat generation.

- Conductors in Charging Piles: High-current conductors made from copper powder can carry higher charging power, helping to achieve ultra-fast charging and shorten charging time.

- Thermal Management Systems: Using the high thermal conductivity of copper powder, high-performance radiators can be manufactured for charging equipment to ensure temperature stability during high-power charging.

- Electromagnetic Shielding: Electromagnetic shielding materials made with copper powder can improve the electromagnetic compatibility of charging equipment, reduce interference with surrounding electronic devices, and enhance charging safety.

For example, a charging equipment company developed a new ultra-fast charging gun using specially treated copper powder to make the contacts, which not only improved charging efficiency but also reduced temperature rise during charging by 20%, greatly enhancing the user charging experience.

Future Development and Application Prospects of Copper Powder

Looking ahead, with the continuous advancement of electric vehicle technology and the growing market demand, copper powder has broader application prospects in the field of new energy vehicles. Its applications cover multiple key areas, including batteries, motors, electronic controls, and charging equipment, playing a crucial role in promoting the development of the new energy vehicle industry.

In addition, with the progress of technology, the potential for copper powder applications in emerging technologies such as solid-state batteries, the Internet of Vehicles (IoV), and wireless charging will gradually become apparent, bringing more innovation and breakthroughs to the future transportation system.

Taiwanese companies' advantages in materials science and manufacturing processes will place them in an important position in this field and make significant contributions to the global development of the new energy vehicle industry.