New Generation Copper Powder Surface Treatment Technology: Key Techniques to Enhance Product Stability

Last updated on August 13, 2024

Technological Breakthroughs and Key Innovations

In the field of material science, every small breakthrough can trigger a wave of innovation. Recently, the development of a new generation of surface treatment technology for copper powder has brought significant performance improvements. This technology focuses on enhancing the stability of copper powder, addressing long-standing issues in the industry such as copper powder oxidation and poor dispersibility.

The core of this technology lies in a brand-new surface modification method, which includes the following innovations:

- Nanometer-level surface coating

- Multi-functional surface modification

- Improved oxidation resistance

- Environmentally friendly and non-toxic treatment

Applications and Technical Advantages

This new technology has demonstrated superior performance in various application fields, particularly in high-frequency communications, conductive pastes, thermal management materials, and 3D printing, showing immense technological potential.

Specific applications include:

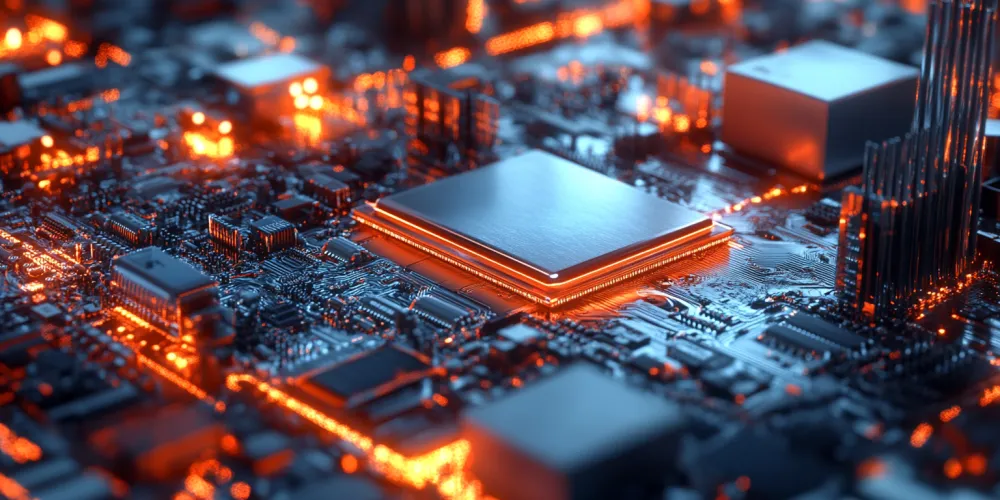

- Printed Circuit Board (PCB) Manufacturing

- Conductive Pastes

- Thermal Management Materials

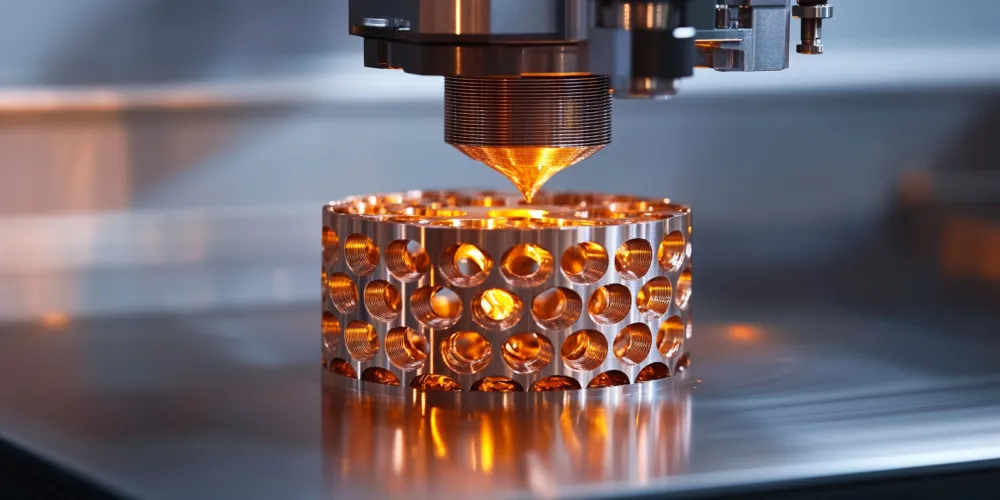

- 3D Printing Materials

Research Challenges and Technical Solutions

During the development process, the research team faced numerous challenges, overcoming which laid a solid foundation for the success of the technology.

Here are some of the key challenges and their solutions:

- Selection of Technical Routes

- Optimization of Process Parameters

- Innovation in Equipment

- Verification of Product Performance

Future Prospects of Technology Application

As the technology continues to mature, it is expected to play a role in more high-end application fields, particularly in submicron particle size, conductive adhesives, EMI shielding, and other areas, bringing new technological innovations.

The further application of this technology may promote the development of porous materials and metal composite materials, providing technical support for improving the performance of the next generation of electronic components such as MLCC (Multilayer Ceramic Capacitors).

In the future, with the integration of more innovative technologies, this technology is expected to become a significant driving force in the field of material science.

We will continue to dedicate ourselves to developing new materials science technologies.