Eco-Friendly Cuprous Oxide Technology Overview

This article was last updated on August 13, 2024

Introduction to Innovative Processes

Green technology plays a crucial role in modern industry, not only driving industrial upgrades but also making a significant contribution to environmental protection. This article introduces a Cuprous Oxide (Cu2O) production technology that drastically reduces energy consumption and emissions while improving product quality.

The core innovations of this technology include the following aspects:

- Green Raw Material Selection: Utilizes renewable resources as the main raw materials, reducing dependence on mineral resources and embodying the concept of a circular economy.

- Precision Control System: Introduces an advanced intelligent control system that enables fully automated operation, optimizing production parameters to improve product quality and production efficiency.

- Innovative Waste Gas Treatment: Employs multi-stage adsorption purification technology to effectively remove harmful gases produced during manufacturing, achieving a waste gas treatment efficiency that far exceeds environmental standards.

Economic Benefits and Market Prospects

This new process not only brings significant environmental benefits but also shows great potential in economic terms. By reducing production costs and improving product quality, this technology demonstrates stronger competitiveness in the market and provides conditions for entering the high-end electronic materials market. With the increasing popularity of eco-friendly products, the market outlook is also becoming broader.

Technological Innovations and Outlook

The success of the eco-friendly Cuprous Oxide (Cu2O) process is rooted in long-term technological innovation. Major technological innovations achieved during the development process include:

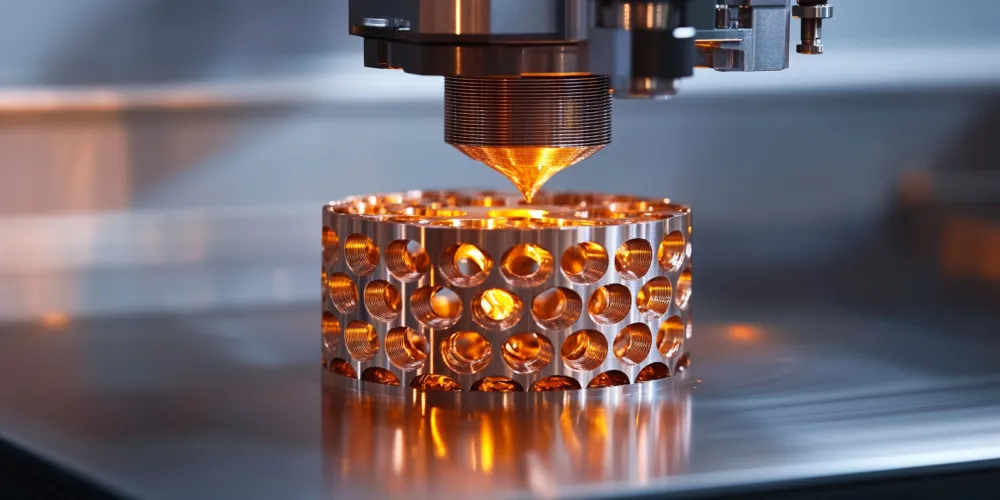

- Nano Catalysis Technology: Developed highly efficient nano-scale copper-based catalysts that lower reaction temperatures and reduce production costs.

- Precision Oxygen Control Technology: Utilized advanced oxygen concentration monitoring and control systems to achieve precise regulation of the oxidation process, improving product quality.

- Intelligent Manufacturing System: Introduced artificial intelligence and big data technologies to achieve intelligent management throughout the process, continuously improving production efficiency.

- Modular Design: The modular production line design enhances production flexibility, allowing quick adaptation to changes in market demand.

Social Responsibility and Sustainable Development

Corporate development and social responsibility are closely linked. Promoting the eco-friendly Cuprous Oxide (Cu2O) production process reflects the company's commitment to technological innovation and active fulfillment of social responsibility.

This initiative showcases the company's responsibility in environmental protection, employee well-being, community relations, and industry leadership, driving the entire industry towards a greener and more sustainable direction.